Choosing the perfect bath accessory is often an afterthought, but it is one of the most critical decisions for your daily skincare routine. A Bath Sponge Scourer is more than just a tool to soap up; it is a specialized instrument designed to manage skin texture, hygiene, and health. The debate betwe...

READ MOREProducts

Loofah Cellulose Sponge Scourer Suppliers

Loofah cellulose sponge scourer: the wood pulp cotton body, one side of the wood pulp cotton body surface is arranged with the loofah body, the sewing thread is arranged between the wood pulp cotton body and the loofah body, the washing mark is arranged between the wood pulp cotton body and the loofah body, the shape of the wood pulp cotton body and the loofah body are oval. The utility model provides a loofah wood pulp and cotton cleaning rub. The surface of the loofah body is provided with a wood pulp and cotton body, which can improve the cleaning function of the cleaning rub, can be cleaned in different ways, and is also conducive to improving the practicability of the cleaning rub. A washing mark is arranged between the loofah body and the wood pulp and cotton body to facilitate the operator to clean correctly. The sewing thread between the loofah body and the wood pulp cotton body is conducive to improving the steadiness of the cleaning rub and preventing damage after long-term use.

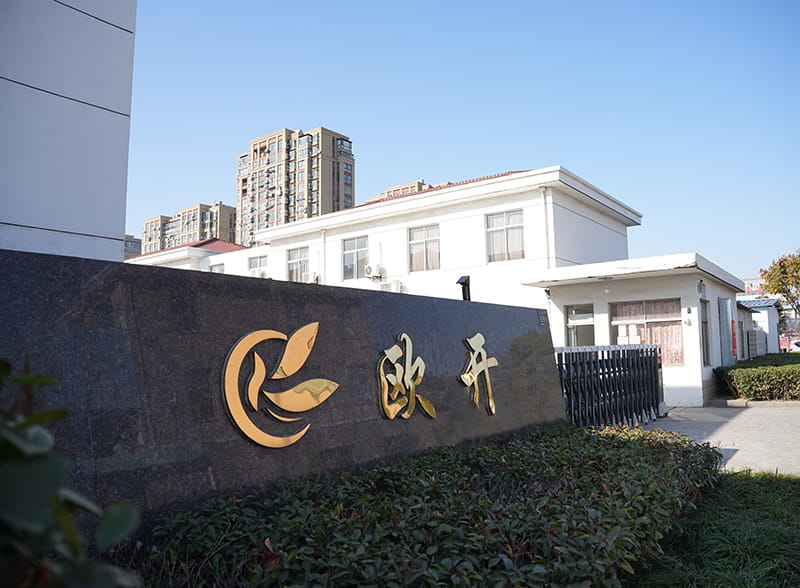

Yancheng Oukai Sponge Products Co., Ltd. was established in 2009 and covers an area of 10000 square meters.It is China Loofah Cellulose Sponge Scourer Manufacturers and Wholesale Loofah Cellulose Sponge Scourer Suppliers, Our company is located in Dafeng city. The traffic here is very convenient: only 40 kilometers from Yancheng Airport, and 30 kilometers from Dafeng Port. Our company will always follow the operation philosophy of "people-oriented, good faith, quality assurance " to provide high-quality sponge products for all clients both at home and abroad.

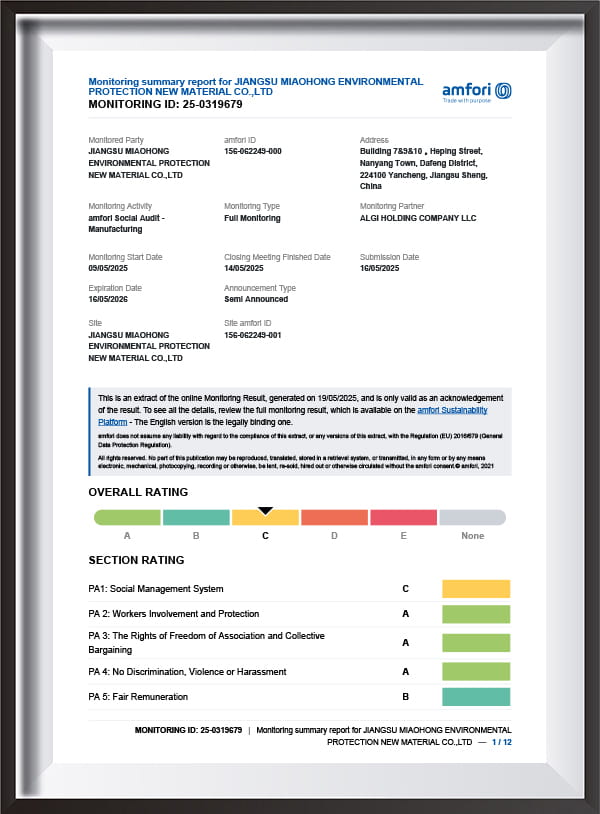

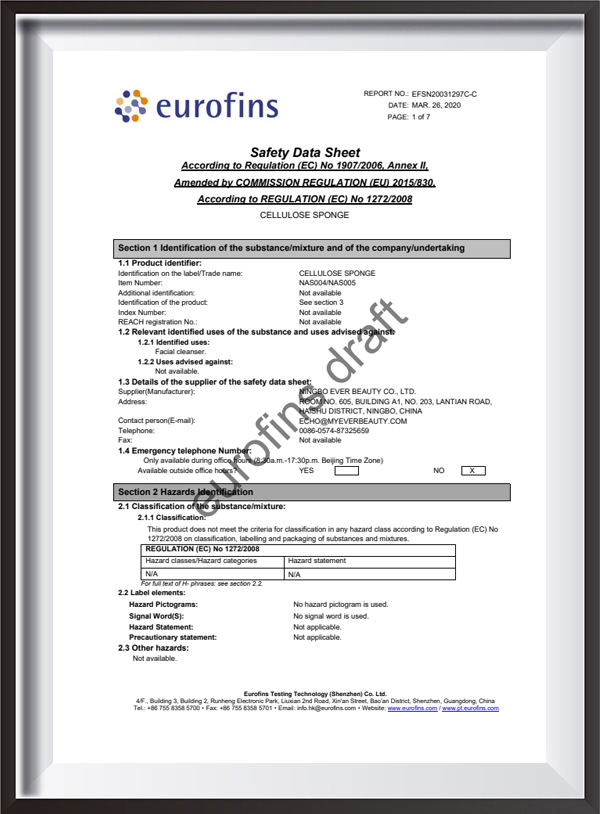

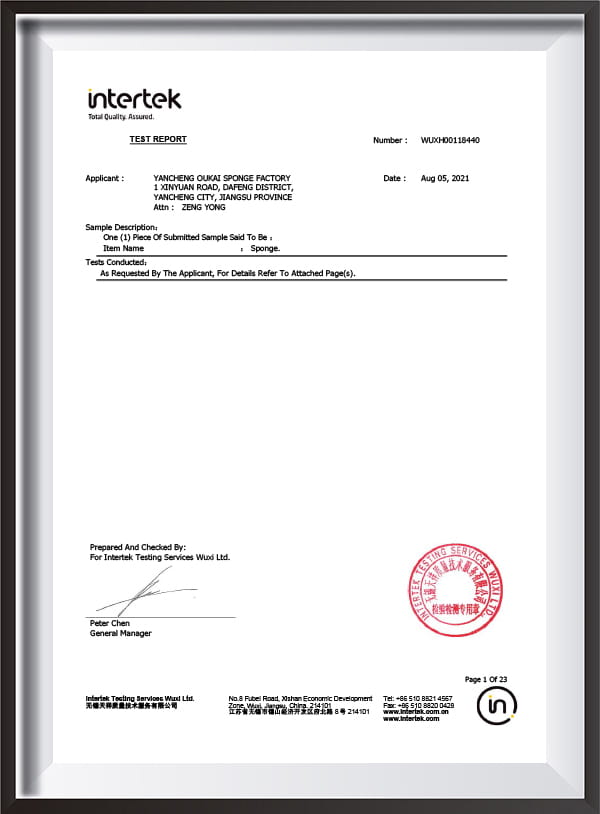

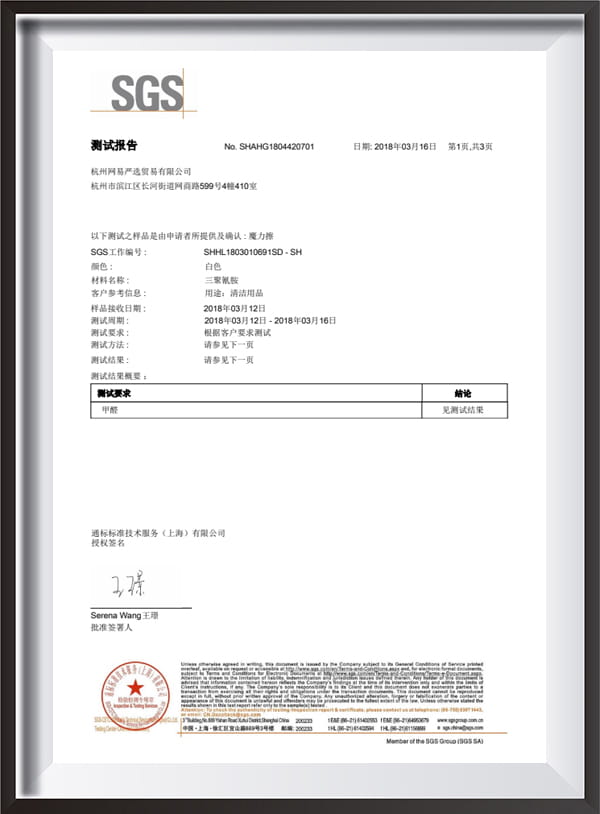

Our factory builds a unique processing and quality control system after a dozen years of exploration and practice. Our factory has already passed ISO 9001 quality and BSCI audits.

The company has developed more than 200 kinds of sponges, developed and produced more than 3000 kinds of sponge products, and created the Foamstar international trademark, to meet your diversified needs. The company mainly produces and sells the following products: Polyester, polyether sponge sponges (flame retardant sponge, filtration sponge, sound-absorbing sponge, anti-static sponge, seaweed cotton/coral sponge, slow rebound sponge, insulation, cleaning sponge, packing sponge), melamine sponge, wood pulp sponge (cellulose sponge), wood pulp cotton cloth, household cleaning (sponge, emery sponge, mesh cloth, microfiber cloth, cleaning brush, cleaning ball, garbage bags, plastic wrap, plastic bag), car cleaning, personal care products. Products continue to be sold to Japan, South Korea, the United States, Germany, Sweden, Britain, Canada, Australia, New Zealand, France, Italy, the Netherlands, Poland, Belgium, Spain, Russia, Chile, the United Arab Emirates, Brazil, Thailand and other more than 40 countries.

We have the advanced production equipment to meet the increasing demands of the market, as well as experienced designers and workers and a management system to help our products stand out from the others. We are a large-scale responsible factory, and the vast majority of our customers have given us a good reputation, We look forward to cooperating with you.

-

-

Microfiber sponges are advanced cleaning tools made from ultra-fine synthetic fibers, often a blend of polyester and polyamide. Unlike traditional sponges, the microfibers are thousands of times finer than human hair, which allows them to capture and hold dirt, dust, grease, and even bacteria more e...

READ MORE -

When it comes to choosing the right sponge for cleaning tasks, many people opt for synthetic sponges due to their availability and low cost. However, cellulose sponges are gaining popularity for their superior performance and eco-friendliness. 1. Eco-Friendly and Biodegradable One of the most compel...

READ MORE

Durability and Long-Lasting Performance of Loofah Cellulose Sponge Scourer

The durability of Loofah Cellulose Sponge Scourers is largely determined by the composition of natural loofah fibers combined with high-quality cellulose, creating a structure that balances strength, flexibility, and absorbency. At Yancheng Oukai Sponge Products Co., Ltd., we carefully select loofah and cellulose fibers based on tensile strength, fiber length, and natural abrasiveness to achieve a sponge that maintains its integrity over repeated cleaning cycles. The interweaving of fibers ensures that the sponge resists tearing and deformation, even under high-pressure scrubbing. The cellulose component enhances water retention, allowing the sponge to remain soft and pliable while maintaining structural rigidity. Unlike synthetic alternatives, our Loofah Cellulose Sponge Scourers retain their shape and scrubbing power, ensuring consistent cleaning performance throughout the sponge’s lifecycle.

Yancheng Oukai Sponge Products Co., Ltd. utilizes proprietary blending techniques to create a uniform density throughout the sponge, which reduces the risk of weak points that could compromise durability. Furthermore, our sponge scourers are tested under controlled laboratory conditions, including wetting, drying, and mechanical stress simulations, to ensure long-term reliability. By using a combination of natural materials and precision manufacturing, Yancheng Oukai Sponge Products Co., Ltd. delivers Loofah Cellulose Sponge Scourers that combine environmental sustainability with functional resilience. This careful attention to fiber selection, bonding, and density creates a product that consistently withstands repeated scrubbing and exposure to varying cleaning conditions without degradation, setting a benchmark for performance in both household and industrial environments.

At Yancheng Oukai Sponge Products Co., Ltd., manufacturing precision is a key factor that contributes to the durability and longevity of Loofah Cellulose Sponge Scourers. Every batch of sponge scourers undergoes a combination of automated and manual inspections to verify fiber alignment, density, and surface texture. The automated machinery evaluates compression resistance and tensile strength, while skilled technicians assess the sponge’s ability to withstand repeated mechanical stress, ensuring that our products consistently meet high standards. The blending process of loofah and cellulose fibers is calibrated to optimize bonding without compromising flexibility, which enables our sponges to retain their abrasive effectiveness while resisting tearing. The factory’s processing techniques minimize the formation of weak points, preventing premature degradation during normal and heavy-duty use.

Yancheng Oukai Sponge Products Co., Ltd. implements water-resistance and chemical-resistance testing for each batch, simulating prolonged exposure to detergents, cleaning solutions, and temperature fluctuations. These tests confirm that our Loofah Cellulose Sponge Scourers maintain structural integrity and cleaning efficiency even under challenging conditions. Quality control measures also include surface smoothness testing to avoid fiber shedding that could reduce sponge life. By integrating advanced technology with hands-on craftsmanship, Yancheng Oukai Sponge Products Co., Ltd. ensures that our Loofah Cellulose Sponge Scourers consistently offer long-lasting performance, making us a trusted supplier for clients in over 40 countries. Every sponge reflects a balance of natural material resilience and engineered precision, providing a cleaning solution that performs reliably throughout its lifespan.

Loofah Cellulose Sponge Scourers from Yancheng Oukai Sponge Products Co., Ltd. are engineered to maintain high performance under continuous and rigorous cleaning tasks. The combination of natural loofah fibers and cellulose allows the sponge to absorb water efficiently while maintaining scrubbing effectiveness, even after prolonged use. Our sponges resist compression and retain their original shape, preventing sagging or deformation that could reduce cleaning efficiency. Yancheng Oukai Sponge Products Co., Ltd. conducts extensive performance testing in simulated real-world scenarios, including scrubbing cookware, countertops, tiles, and other surfaces, to ensure consistent results. The fiber composition allows the sponge to remove dirt, grease, and stains without damaging delicate surfaces, making it suitable for both household and commercial applications. Unlike synthetic alternatives, our sponge scourers do not degrade rapidly or lose flexibility over repeated cycles of wetting and drying.

The cellulose structure retains its softness while the loofah fibers continue to provide mild abrasiveness, which ensures that our sponges maintain cleaning effectiveness over months of repeated use. The manufacturing process at Yancheng Oukai Sponge Products Co., Ltd. also ensures uniform density across the sponge, preventing uneven wear during heavy scrubbing. These qualities make the Loofah Cellulose Sponge Scourers reliable for kitchens, bathrooms, industrial cleaning, and professional environments where long-lasting performance is essential. Our clients can rely on our sponges to provide consistent results and maintain their durability over extended periods of frequent use, reflecting our commitment to high-quality and sustainable cleaning solutions.

The ability of Loofah Cellulose Sponge Scourers to withstand chemical and environmental stress is a defining factor in their long-lasting performance. Yancheng Oukai Sponge Products Co., Ltd. designs our sponge scourers to maintain structural integrity when exposed to detergents, acidic or alkaline cleaning agents, and hot water. The loofah fibers provide natural abrasion while the cellulose component resists weakening caused by chemical exposure. This combination ensures that our sponges do not deteriorate under typical household or industrial cleaning conditions. In addition, our Loofah Cellulose Sponge Scourers are tested for performance under prolonged moisture exposure to prevent softening, fiber loss, or microbial growth.

Yancheng Oukai Sponge Products Co., Ltd. uses a precise drying and bonding process during manufacturing to reduce water retention in non-functional areas, allowing the sponge to dry efficiently after use while maintaining resilience. The result is a sponge that withstands repeated immersion, scrubbing, and drying cycles without compromising cleaning performance or structural integrity. Environmental stress, including variations in water temperature and humidity, also has minimal effect on our sponges due to the natural elasticity and bonding of the fibers. These properties make our Loofah Cellulose Sponge Scourers ideal for diverse cleaning environments, from commercial kitchens to industrial settings, ensuring that clients receive a reliable, high-performing product capable of withstanding the demands of regular use over extended periods.

English

English