Choosing the perfect bath accessory is often an afterthought, but it is one of the most critical decisions for your daily skincare routine. A Bath Sponge Scourer is more than just a tool to soap up; it is a specialized instrument designed to manage skin texture, hygiene, and health. The debate betwe...

READ MOREProducts

Sponge Brush Suppliers

A sponge brush is an artifact for washing cups. The handle is separated from the sponge in front, and it can be inserted together when used. The bottom of the Cup is difficult to brush. We make full use of the sponge, and the bottom and side can be fully cleaned. It is difficult to wipe the bottom of the Cup with a high-water cup. The sponge Cup brush is in use. Turn the handle and wipe it clean a few times. Of course, there is no problem with ceramic cups.

Yancheng Oukai Sponge Products Co., Ltd. was established in 2009 and covers an area of 10000 square meters.It is China Sponge Brush Manufacturers and Wholesale Sponge Brush Suppliers, Our company is located in Dafeng city. The traffic here is very convenient: only 40 kilometers from Yancheng Airport, and 30 kilometers from Dafeng Port. Our company will always follow the operation philosophy of "people-oriented, good faith, quality assurance " to provide high-quality sponge products for all clients both at home and abroad.

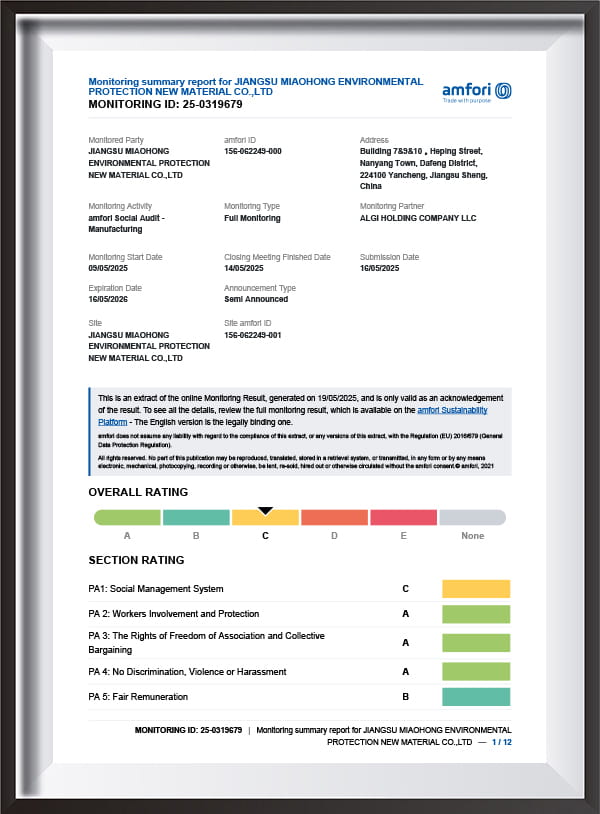

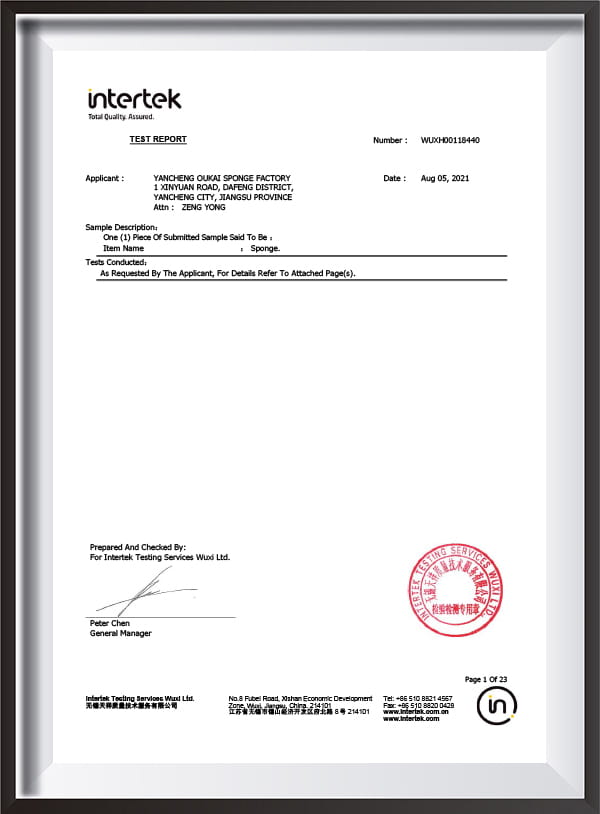

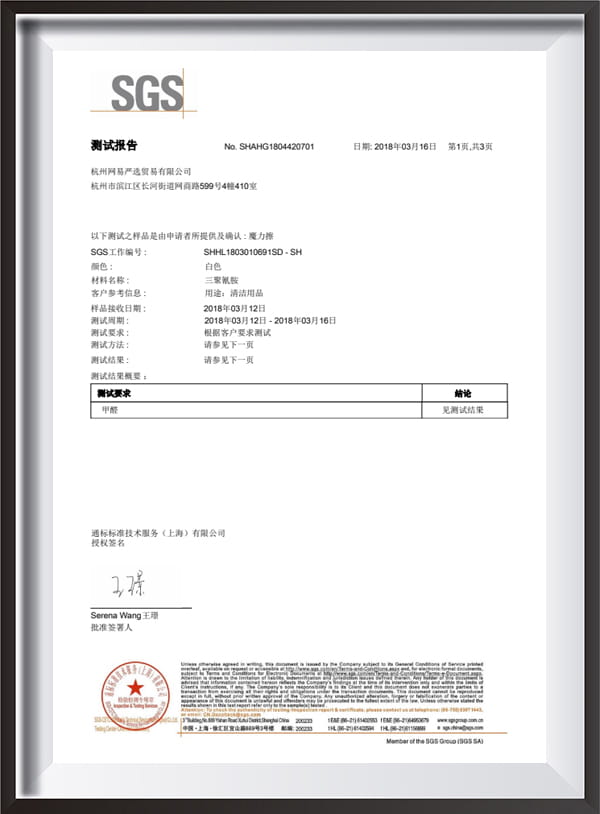

Our factory builds a unique processing and quality control system after a dozen years of exploration and practice. Our factory has already passed ISO 9001 quality and BSCI audits.

The company has developed more than 200 kinds of sponges, developed and produced more than 3000 kinds of sponge products, and created the Foamstar international trademark, to meet your diversified needs. The company mainly produces and sells the following products: Polyester, polyether sponge sponges (flame retardant sponge, filtration sponge, sound-absorbing sponge, anti-static sponge, seaweed cotton/coral sponge, slow rebound sponge, insulation, cleaning sponge, packing sponge), melamine sponge, wood pulp sponge (cellulose sponge), wood pulp cotton cloth, household cleaning (sponge, emery sponge, mesh cloth, microfiber cloth, cleaning brush, cleaning ball, garbage bags, plastic wrap, plastic bag), car cleaning, personal care products. Products continue to be sold to Japan, South Korea, the United States, Germany, Sweden, Britain, Canada, Australia, New Zealand, France, Italy, the Netherlands, Poland, Belgium, Spain, Russia, Chile, the United Arab Emirates, Brazil, Thailand and other more than 40 countries.

We have the advanced production equipment to meet the increasing demands of the market, as well as experienced designers and workers and a management system to help our products stand out from the others. We are a large-scale responsible factory, and the vast majority of our customers have given us a good reputation, We look forward to cooperating with you.

-

-

Microfiber sponges are advanced cleaning tools made from ultra-fine synthetic fibers, often a blend of polyester and polyamide. Unlike traditional sponges, the microfibers are thousands of times finer than human hair, which allows them to capture and hold dirt, dust, grease, and even bacteria more e...

READ MORE -

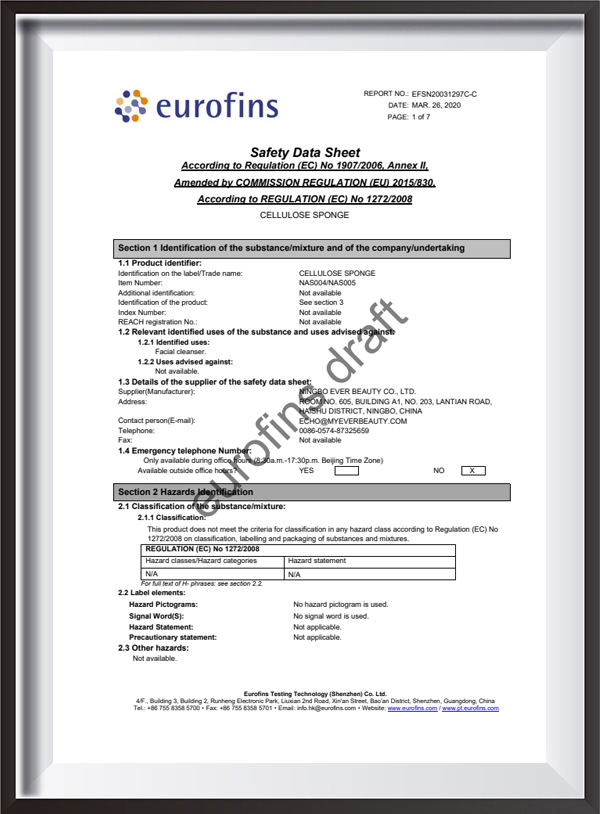

When it comes to choosing the right sponge for cleaning tasks, many people opt for synthetic sponges due to their availability and low cost. However, cellulose sponges are gaining popularity for their superior performance and eco-friendliness. 1. Eco-Friendly and Biodegradable One of the most compel...

READ MORE

Redefining Cleaning and Application: The Multidimensional World of the Sponge Brush

In the realm of modern household cleaning and industrial application, the evolution of tools never ceases. The Sponge Brush, a tool that appears simple yet is steeped in material science, has long surpassed the basic combination of a sponge and a handle. As a leading manufacturer in the industry, Yancheng Oukai Sponge Products Co., Ltd. has been dedicated to exploring the infinite possibilities of this tool since its establishment in 2009. Within our 10,000-square-meter modern production base, we have witnessed the Sponge Brush evolve from a singular cleaning implement into a multifunctional solution spanning art, industry, automotive detailing, and personal care.

Material Science and Structural Advantages

The core competitiveness of a high-quality Sponge Brush lies in the microporous structure of the sponge itself. Unlike ordinary sponges, the Sponge Brush produced by Yancheng Oukai Sponge Products Co., Ltd. utilizes precision-engineered polyurethane (PU), polyether, and advanced wood pulp fiber (cellulose). The choice of these materials directly determines the tool's liquid absorption rate, resilience, and chemical resistance.

At the macroscopic level, the design of a Sponge Brush considers fluid dynamics. When the brush head contacts a surface, the open-cell structure within the sponge acts like countless microscopic reservoirs. This ensures that during the coating process, liquid is released at a constant rate, avoiding the common "sagging" effect found with traditional brushes. By continuously fine-tuning the formulas for polyester and polyether sponges, Yancheng Oukai Sponge Products Co., Ltd. ensures that our Sponge Brush maintains excellent control regardless of the fluid's viscosity.

Why the Sponge Brush is Irreplaceable

Compared to traditional bristle brushes, the mechanical structure of a Sponge Brush allows it to release internal liquids uniformly under pressure. This "controlled release" mechanism makes it ideal for handling expensive stains or delicate cleaning agents, significantly reducing waste and dripping. After over a decade of exploration and practice, Yancheng Oukai Sponge Products Co., Ltd. has established a unique processing and quality control system. This ensures that every Sponge Brush meets the rigorous ISO 9001 standards, providing superior tactile feedback and durability to customers in over 40 countries.

Furthermore, the edge-cutting technology of the Sponge Brush is a key reason for its irreplaceability. We use precision CNC machinery to cut the sponge, ensuring every bevel fits perfectly into complex corners and edges. This geometric precision makes the Sponge Brush perform effortlessly in architectural decoration and fine handicrafts. Our factory builds a unique processing and quality control system after a dozen years of exploration and practice, ensuring every unit stands out in the global market.

The All-Rounder in Household Cleaning

In the domestic environment, the application scenarios for the Sponge Brush are ubiquitous. From greasy kitchens to damp bathrooms, it has become synonymous with cleaning efficiency due to its flexible and versatile forms.

The Kitchen Battlefield

The kitchen is the primary arena for the Sponge Brush. For non-stick pans, a Sponge Brush with a specialized coating can remove charred residue without damaging the Teflon surface. For slender glasses or irregularly shaped tableware, the handled design ensures no dead zones are left uncleaned. The high-density Sponge Brush developed by Yancheng Oukai Sponge Products Co., Ltd. generates fine, rich foam, greatly enhancing cleaning productivity.

When dealing with heavy oil in areas like range hoods, the adsorption capacity of the Sponge Brush is particularly prominent. Unlike ordinary rags that simply smear oil around, a high-quality Sponge Brush locks grease deep within its pores, requiring only a simple rinse to restore cleanliness. Our range of household cleaning products, including emery sponges and mesh cloth, complements the Sponge Brush to provide a total kitchen solution.

Bathroom and Corner Cleaning

Tile gaps and limescale at the base of faucets are common pain points in home cleaning. By adjusting the hardness and shape of the sponge, a dedicated Sponge Brush can penetrate deep into crevices. Furthermore, brushes made from our anti-static sponges can safely clean dust from keyboards, TV screen bezels, and other precision electronic devices without causing scratches or electrostatic damage.

Core Parameter Comparison: Sponge Material Performance

To assist users in choosing the most suitable Sponge Brush, below is a comparison of core materials produced by Yancheng Oukai Sponge Products Co., Ltd.:

| Performance Metric | Polyester/Polyether Sponge | Cellulose (Wood Pulp) | Melamine Sponge |

| Absorption Ratio | 10x - 15x | 20x - 25x | 5x - 8x |

| Abrasion Resistance | Very High | Medium | Low (Wears with use) |

| Chemical Resistance | Excellent | Average | Excellent |

| Primary Scenarios | Painting, Heavy Oil | Dishwashing, Wiping | Stubborn Stains |

| Eco-Attribute | Synthetic, Long-life | Biodegradable | Chemical Synthesis |

| Density (PPI) | 20 - 100 Adjustable | Irregular Natural | Ultrafine Structure |

The Soul Tool for Art and Handicrafts

For artists and DIY enthusiasts, the Sponge Brush is more than just a cleaning tool; it is an extension of creativity. In the world of art, it breaks the limitations of traditional brushes, granting works a unique texture.

Texture Master in Painting

In acrylic or watercolor painting, using a Sponge Brush to dab or drag pigment creates gradient effects impossible with traditional bristles. Especially in large-area base coating, the uniform pores of the sponge ensure color consistency and prevent messy brushstrokes. This "uniform diffusion" makes the Sponge Brush the ideal choice for rendering vast areas like skies and oceans. Our Foamstar international trademark was created specifically to meet these diversified creative needs.

Professional Choice for Woodworking and Home Decor

When staining wood or applying varnish, the Sponge Brush is the professional craftsman's first choice. Traditional bristle brushes often leave brush marks, whereas a Sponge Brush evenly presses the coating into the wood fibers, resulting in a silky, flat finish. The Foamstar brand series from Yancheng Oukai Sponge Products Co., Ltd. features high-quality cutting processes that ensure neat brush edges for precise finishing in corners.

DIY Stencil Printing

In wall decoration or fabric DIY, the Sponge Brush is the best partner for stenciling. It controls the amount of pigment intake, preventing paint from leaking under the stencil edges, thereby ensuring sharp, crisp patterns. Many DIY experts find that dabbing with a Sponge Brush allows for better control over color intensity than using rollers. Our experienced designers and workers help our products stand out in the competitive DIY market.

Global Vision and Specialized Production

As an enterprise deeply rooted in the sponge product sector, the geographical location of Yancheng Oukai Sponge Products Co., Ltd. provides excellent logistical advantages. Located in Dafeng City, we are only 40 kilometers from Yancheng Airport and 30 kilometers from Dafeng Port. This convenience ensures that our Sponge Brush products can rapidly respond to international market demands, reaching customers in Japan, South Korea, the USA, Germany, Sweden, Canada, Australia, and more than 40 other countries.

Our 10,000-square-meter factory is equipped with industry-leading automated production lines. From the initial polyurethane foaming to the final assembly of the Sponge Brush, every step is under strict monitoring. Our ISO 9001 certification and BSCI audit pass signify that while we pursue economic benefits, we also highly value employee welfare and social responsibility. We follow the philosophy of "people-oriented, good faith, quality assurance" to provide high-quality products for all clients.

Diversified Product Matrix

To meet the varied needs of different industries, we have developed over 200 types of sponge raw materials, resulting in more than 3,000 kinds of Sponge Brush and related products. Our product line includes:

- Functional Sponges: Flame retardant, filtration, sound-absorbing, and anti-static sponges.

- Special Texture Sponges: Seaweed, coral, and slow-rebound sponges.

- Household Cleaning: Emery sponges, mesh sponges, and microfiber cloth brushes.

- Professional Care: Specialized automotive detailing sponge brushes and cellulose wiping blocks.

This full-chain production capability allows Yancheng Oukai Sponge Products Co., Ltd. to provide one-stop customization services (OEM/ODM). Whether you need a Sponge Brush of a specific hardness or packaging with specific branding, our team is ready to deliver.

In-Depth Buying Guide: How to Choose the Perfect Sponge Brush

With many types of brushes on the market, not every Sponge Brush can meet professional requirements. When purchasing, focus on the following dimensions:

Head Density and Pore Size

A high-density Sponge Brush feels firm and does not deform excessively after absorbing liquid, making it suitable for fine application and high-viscosity adhesives. Low-density sponges have larger pores, which produce more foam—ideal for large-scale basic cleaning. Yancheng Oukai Sponge Products Co., Ltd. can adjust the PPI (Pores Per Inch) of the sponge based on the customer's specific application.

Handle Engineering

The handle is not just a support; it affects the "feel" of the operation. We offer options including natural wood, reinforced plastic, and ergonomic non-slip handles. Wooden handles provide a traditional texture and balance for art, while plastic handles are more water and corrosion-resistant for kitchen and industrial use.

Connection Strength

The most common failure for a Sponge Brush is the sponge head detaching from the handle. Yancheng Oukai Sponge Products Co., Ltd. utilizes a unique bonding process and reinforced structure to ensure the brush head remains stable even when soaked in solvents or subjected to intense friction.

Longevity and Maintenance

While many view the Sponge Brush as a consumable, scientific maintenance can significantly extend its lifespan and reduce waste.

Cleaning Logic

If using water-based paints or cleaners, rinse immediately with warm soapy water and squeeze repeatedly until the water runs clear. For oil-based materials, use the appropriate solvent, but avoid prolonged soaking to prevent structural damage to the sponge. Our polyether and polyester sponges are designed to withstand various chemical cleaning agents.

Drying Environment

After cleaning, the Sponge Brush should be placed in a ventilated area to dry naturally. Avoid direct sunlight, which can make the sponge brittle. Never store it in a sealed container while damp to prevent mold growth. Our factory's quality control system ensures that the materials used have high resistance to environmental degradation.

Physical Inspection

Regularly check the sponge surface. If the pores are clogged with dried paint or if the sponge loses its elasticity, its performance has declined, and it should be replaced. A well-maintained Sponge Brush from Yancheng Oukai Sponge Products Co., Ltd. can last through multiple projects if handled with care.

Industrial Applications: The Invisible Contribution of the Sponge Brush

On many industrial assembly lines, the Sponge Brush acts as an unsung hero. In electronics manufacturing, dust-free Sponge Brush variants are used to clean the edges of silicon wafers in cleanrooms. In the footwear industry, they are used to apply glue evenly, ensuring the strength and aesthetics of the sole bond. Yancheng Oukai Sponge Products Co., Ltd. develops professional-grade brushes with low debris and high chemical stability for these high-standard industries.

In the automotive industry, the application of the Sponge Brush has been refined to the extreme. From cleaning oil in the engine bay to applying nourishing cream to leather seats, every brush is designed for a specific purpose. Our Foamstar series has won the favor of global automotive detailing chains through this professional spirit and our advanced production equipment.

FAQ:

Can a Sponge Brush be used on high-temperature surfaces?

Standard polyurethane Sponge Brush units typically have a heat resistance of 80 degrees Celsius to 100 degrees Celsius. If used on hotter surfaces, the sponge may degrade or melt. For high-temperature scenarios, Yancheng Oukai Sponge Products Co., Ltd. can provide customized heat-resistant materials or insulation sponges.

Why does my sponge brush start shedding after a few uses?

This is usually due to two reasons: contact with strong corrosive solvents that break down the polymer chains, or the use of low-density, inferior sponges. Choosing products from an ISO 9001 certified manufacturer like Yancheng Oukai Sponge Products Co., Ltd. prevents such physical disintegration. Our Sponge Brush units undergo solvent resistance simulation tests before leaving the factory.

How do I use a sponge brush to apply paint without creating bubbles?

Avoid pressing too hard. Pressing forces air out of the sponge and into the paint, creating bubbles. The correct method is to dip the Sponge Brush lightly and apply it with smooth, one-way long strokes. If tiny bubbles appear, they can be smoothed over with a dry brush head that has had the air squeezed out.

Are the products from Yancheng Oukai Sponge Products Co., Ltd. eco-friendly?

We take environmental and social responsibility seriously. Our factory has passed the BSCI audit. Our cellulose Sponge Brush series uses natural plant fibers and is highly biodegradable. We also offer wood pulp cotton cloth and other sustainable household cleaning products to meet the increasing market demand for green solutions.

Can a sponge brush handle rough wood surfaces?

While the Sponge Brush is versatile, extremely rough wood with sharp splinters can tear the sponge. It is recommended to pre-treat the surface with sandpaper (220 grit or higher) or use a traditional bristle brush for the initial rough stage, switching to a Sponge Brush from Yancheng Oukai Sponge Products Co., Ltd. for the final fine coating to ensure a perfect finish.

How do I distinguish between polyester and polyether Sponge Brush materials?

Polyester sponges generally have better tensile strength and solvent resistance, feeling firmer—perfect for mechanical cleaning and oil-based paints. Polyether sponges are softer and have better hydrolysis resistance, making them ideal for water-based cleaning and personal care. Yancheng Oukai Sponge Products Co., Ltd. clearly labels material types to help customers make the best choice for their diversified needs.

English

English