The modern kitchen is equipped with a variety of specialized tools, from high-end ceramic skillets to traditional cast iron. However, the most critical tool for maintaining these investments is often the most overlooked: the Kitchen Clean Sponge. Choosing the wrong texture can be a costly mistake, l...

READ MOREProducts

Car Wash Sponge Brush Suppliers

Car wash sponge brush does not hurt hands or dirty hands. Soft sponge is not harmful to clean face, is not afraid of oil pollution, good water absorption, easy to clean, durable, not easy to break, flexible and elastic. Strong cleaning power, easy to remove oil, strong water absorption, good foaming, rich and suitable for many scenarios.

Yancheng Oukai Sponge Products Co., Ltd. was established in 2009 and covers an area of 10000 square meters.It is China Car Wash Sponge Brush Manufacturers and Wholesale Car Wash Sponge Brush Suppliers, Our company is located in Dafeng city. The traffic here is very convenient: only 40 kilometers from Yancheng Airport, and 30 kilometers from Dafeng Port. Our company will always follow the operation philosophy of "people-oriented, good faith, quality assurance " to provide high-quality sponge products for all clients both at home and abroad.

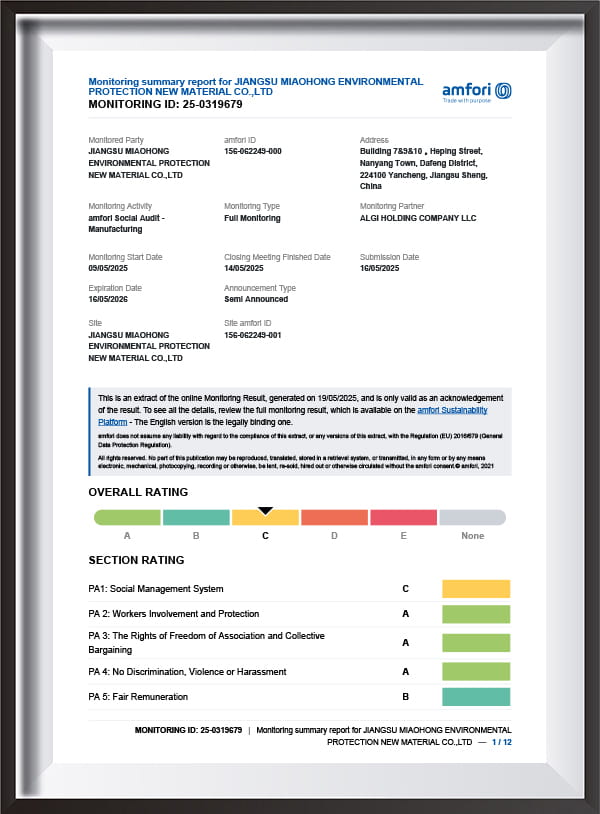

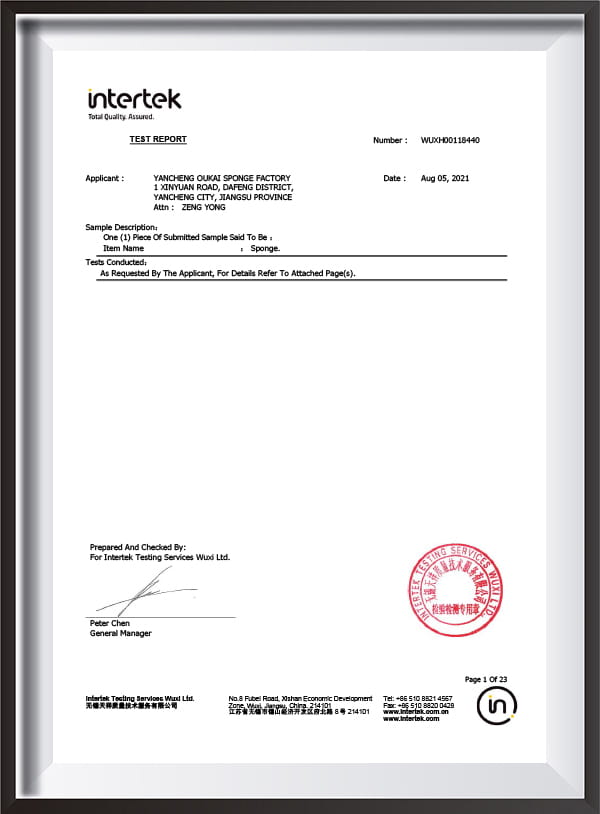

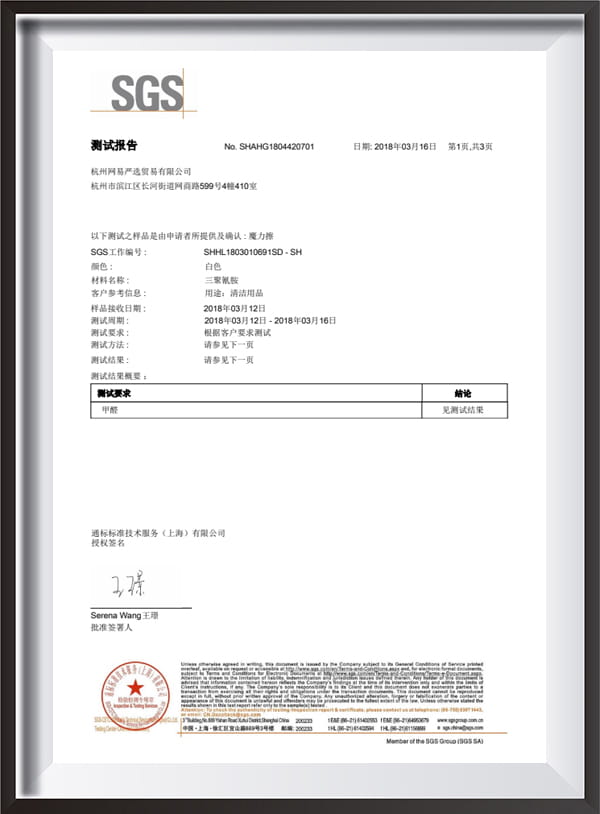

Our factory builds a unique processing and quality control system after a dozen years of exploration and practice. Our factory has already passed ISO 9001 quality and BSCI audits.

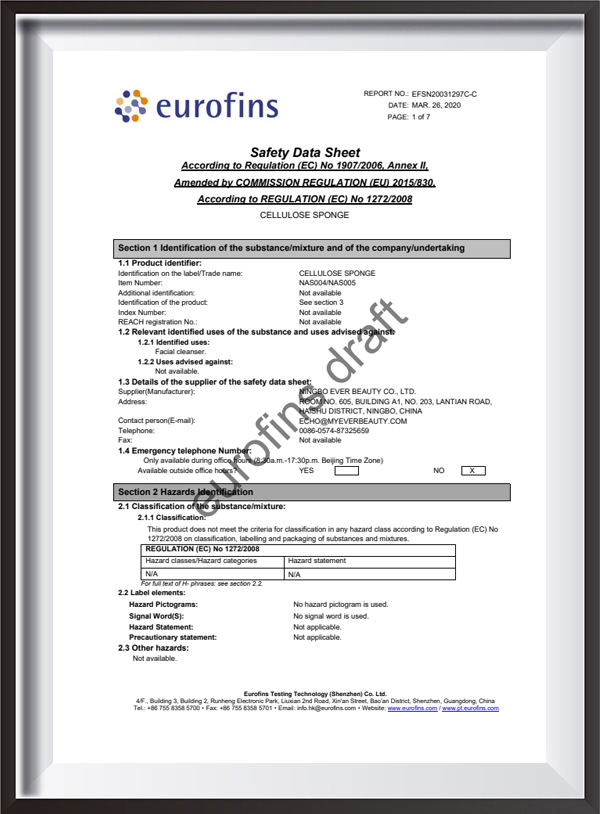

The company has developed more than 200 kinds of sponges, developed and produced more than 3000 kinds of sponge products, and created the Foamstar international trademark, to meet your diversified needs. The company mainly produces and sells the following products: Polyester, polyether sponge sponges (flame retardant sponge, filtration sponge, sound-absorbing sponge, anti-static sponge, seaweed cotton/coral sponge, slow rebound sponge, insulation, cleaning sponge, packing sponge), melamine sponge, wood pulp sponge (cellulose sponge), wood pulp cotton cloth, household cleaning (sponge, emery sponge, mesh cloth, microfiber cloth, cleaning brush, cleaning ball, garbage bags, plastic wrap, plastic bag), car cleaning, personal care products. Products continue to be sold to Japan, South Korea, the United States, Germany, Sweden, Britain, Canada, Australia, New Zealand, France, Italy, the Netherlands, Poland, Belgium, Spain, Russia, Chile, the United Arab Emirates, Brazil, Thailand and other more than 40 countries.

We have the advanced production equipment to meet the increasing demands of the market, as well as experienced designers and workers and a management system to help our products stand out from the others. We are a large-scale responsible factory, and the vast majority of our customers have given us a good reputation, We look forward to cooperating with you.

-

-

Choosing the perfect bath accessory is often an afterthought, but it is one of the most critical decisions for your daily skincare routine. A Bath Sponge Scourer is more than just a tool to soap up; it is a specialized instrument designed to manage skin texture, hygiene, and health. The debate betwe...

READ MORE -

Microfiber sponges are advanced cleaning tools made from ultra-fine synthetic fibers, often a blend of polyester and polyamide. Unlike traditional sponges, the microfibers are thousands of times finer than human hair, which allows them to capture and hold dirt, dust, grease, and even bacteria more e...

READ MORE

In-depth Analysis: What is a Modern Car Wash Sponge Brush?

In the field of automotive detailing, the evolution of tools has always centered on two core dimensions: efficiency and safety. The emergence of the Car Wash Sponge Brush marks a milestone in the transition from traditional manual car washing to semi-automated, professional solutions.

From a physical structure perspective, a high-quality Car Wash Sponge Brush is not simply a sponge on a stick; it is a result of precision material engineering and ergonomic design. Since its establishment in 2009, Yancheng Oukai Sponge Products Co., Ltd. has continuously focused on the research and development of sponge materials within its 10,000-square-meter modern production base. As a company that has passed ISO 9001 quality and BSCI audits, we understand that the pore structure of the sponge directly determines the safety of the paint surface during cleaning.

Physical Structure and Material Science

The core of a modern Car Wash Sponge Brush lies in its porous sponge head design. Unlike ordinary cleaning sponges, professional car wash sponges must possess an extremely high grit-trapping capacity. When the Car Wash Sponge Brush slides across the vehicle surface, its open-cell structure sucks tiny sand particles into the pores, preventing them from acting as an abrasive between the paint and the sponge, thus avoiding the creation of annoying swirl marks.

Yancheng Oukai Sponge Products Co., Ltd. utilizes advanced production equipment to develop various materials, including polyester, polyether, and seaweed/coral sponges, specifically designed to enhance the water retention of the Car Wash Sponge Brush. This means the brush head can carry more lubricating car wash solution during the wiping process, significantly reducing frictional resistance.

The Evolution of the Car Wash Sponge Brush

Primitive Stage: Using newspapers or coarse cloths, which caused significant damage to the paint.

Pure Sponge Stage: Although soft, manual operation was laborious and reaching high areas like the roof was difficult.

Early Brush Stage: Hard plastic bristles appeared; while they had long handles, they easily scratched the clear coat.

Modern Car Wash Sponge Brush Stage: Combining polymer sponge technology with lightweight alloy or composite handles to achieve a perfect balance between cleaning power and safety.

Core Categories: Finding the Best Car Wash Sponge Brush for Your Vehicle

To meet the diversified needs of clients in more than 40 countries, the Foamstar international trademark under Yancheng Oukai Sponge Products Co., Ltd. has developed over 3,000 types of sponge products. For the car wash sector, the Car Wash Sponge Brush is mainly divided into the following categories, each with unique technical parameters:

Comparison of Common Materials

| Performance Index | Chenille Sponge Brush | High-Density PU Sponge Brush | Seaweed/Coral Sponge Brush |

| Water Absorption | Extremely High (10x+ weight) | Medium | High |

| Foaming Performance | Excellent | Superb | Excellent |

| Cleaning Ability | Strong (for heavy mud) | Fine (for oil films/dust) | Balanced (multi-purpose) |

| Tactile Softness | Soft | Extremely Soft | Honeycomb Elasticity |

| Durability | Very High | High | Medium |

Telescoping Handle Car Wash Sponge Brush

This is currently the most popular type on the market, especially for large SUVs, pickups, or RVs. Its advantages include:

Reachability: The telescoping handle design allows users to clean the roof without a ladder.

Ergonomics: It reduces the burden on the waist. Combined with the lightweight high-density sponges produced by Yancheng Oukai Sponge Products Co., Ltd., users will not feel fatigued even after long periods of operation.

Handheld Detail Car Wash Sponge Brush

This type of Car Wash Sponge Brush focuses on the fine cleaning of complex areas such as wheels, grills, and side mirrors.

The detail brushes in the Foamstar international trademark series usually feature a denser pore design to ensure sufficient support when dealing with stubborn stains.

Flow-through Car Wash Sponge Brush

This product realizes the function of rinsing while brushing. Water flows through the handle directly into the interior of the sponge, continuously washing away impurities from the sponge surface.

Technical Requirements: This places extremely high demands on the filtration sponge performance. The filtration sponges produced by Yancheng Oukai Sponge Products Co., Ltd. can withstand continuous water pressure without structural collapse, ensuring the long-term use of the Car Wash Sponge Brush.

As a company following the philosophy of "people-oriented, good faith, quality assurance," we provide high-quality products to clients in the USA, Germany, Japan, Sweden, and beyond, ensuring every Car Wash Sponge Brush meets international standards.

Technical Parameters and Science: How the Car Wash Sponge Brush Protects Paint

In surface treatment, the performance of a Car Wash Sponge Brush is based on rigorous fluid mechanics and material mechanics. Yancheng Oukai Sponge Products Co., Ltd. precisely controls the physical parameters of every sponge at its production base to ensure optimal protection.

Porosity and Particle Embedding Science

The core logic of the Car Wash Sponge Brush in protecting paint lies in its "silt capacity." Tiny sand particles must be quickly moved away from the contact layer. The high-end Car Wash Sponge Brush produced by Yancheng Oukai Sponge Products Co., Ltd. features an optimized open-cell ratio. High porosity means there is enough space inside the sponge to absorb sand under pressure, keeping it away from the paint.

Surface Tension and Foam Stability

Foam provides a lubricating interface. A high-quality Car Wash Sponge Brush must be able to modify the surface tension of the car wash liquid.

Foam Capture: The complex internal structure introduces air into the liquid through mechanical agitation.

Liquid Retention: Our Foamstar products use a special polyester process to enhance capillary action, allowing the brush head to lock in large amounts of foamy fluid to keep the paint wet.

Pressure Distribution Comparison

Standard manual sponges create high, uneven pressure points (fingertip pressure). A professional Car Wash Sponge Brush distributes pressure evenly through its arm structure.

| Pressure Parameter | Traditional Manual Sponge | Professional Car Wash Sponge Brush |

| Average Pressure | High and Uneven | Low and Evenly Distributed |

| Peak Pressure Mitigation | Poor (easy to scratch) | Excellent (buffered by handle) |

| Friction Coefficient | 0.35 - 0.45 | 0.15 - 0.25 (sustained lubrication) |

| Mechanical Efficiency | Lower | Increased by over 40% |

Practical Tutorial: Using a Car Wash Sponge Brush for Professional Results

Correct operating procedures (SOP) are essential to maximize the potential of Yancheng Oukai Sponge Products Co., Ltd. products.

Step 1: The Pre-wash Stage

Before the Car Wash Sponge Brush touches the body, a high-pressure water stream must be used to wash away loose dust. This prevents "large particle damage."

Step 2: Two-Bucket Method

Dip the Car Wash Sponge Brush into the wash solution bucket until saturated with foam.

Slide across the surface with minimal force.

After cleaning one panel, agitate the brush head in a clean water bucket to release dirt using the sponge's resilience.

Redip into the wash solution and repeat.

Step 3: Top-to-Bottom Logic

Always start using the Car Wash Sponge Brush from the roof, followed by the windshield, hood, and sides. This ensures dirt does not flow onto already cleaned areas.

Step 4: Force Control

Using the lightweight handles designed by Yancheng Oukai Sponge Products Co., Ltd., the operator should rely on the wet weight of the brush head. No additional downward pressure is needed; the fibers and pores will handle the adsorption.

Maintenance: Secrets to Extending the Life of Your Car Wash Sponge Brush

Yancheng Oukai Sponge Products Co., Ltd. cares about the user experience. Proper maintenance can significantly extend the life of a Car Wash Sponge Brush:

Deep Cleaning: After use, rinse the sponge head repeatedly with plenty of clean water. Our polyether sponges have excellent chemical resistance against residual detergents.

Avoid Sun Exposure: While our products have UV resistance, long-term exposure can make the polymer brittle. Dry in a cool, ventilated place.

Separated Storage: Brushes used for the body and those used for wheels should be stored separately to prevent metallic powder cross-contamination.

Buying Guide: Avoiding Pitfalls When Choosing a Car Wash Sponge Brush

Based on our experience exporting to over 40 countries, Yancheng Oukai Sponge Products Co., Ltd. suggests these dimensions for selection:

1. Industrial Design of the Handle and Connection

A high-quality Car Wash Sponge Brush must have a stable structure.

Material: Prefer anodized aluminum or high-strength composite plastic. Our process ensures the handle won't rust when exposed to car wash chemicals.

Locking Mechanism: Check the telescoping lock. Inferior brushes might collapse under pressure; our products are pressure-tested for stability.

2. Tactile Feel and Rebound of the Sponge Head

Density Test: Press the sponge. High-quality sponges (like the Foamstar series) feature excellent rebound to fit vehicle curves.

Pore Uniformity: Uniform pores ensure stable foaming and even pressure, a hallmark of the advanced equipment at Yancheng Oukai Sponge Products Co., Ltd.

3. Maintainability and Compatibility

A sustainable Car Wash Sponge Brush should allow for head replacement. Our factory has developed over 200 sponge types, allowing customers to replace only the head rather than the whole tool.

Science FAQ: Car Wash Sponge Brushes and Paint Health

The technical team at Yancheng Oukai Sponge Products Co., Ltd. has compiled this information to improve car care awareness.

How are "Swirl Marks" created?

Swirl marks occur when tools fail to isolate sand. A professional Car Wash Sponge Brush uses deep-capture technology to hold sand in the middle layer, away from the paint.

Chemical Compatibility of Sponge Materials

Car wash liquids vary in pH. The polyester and polyether sponges from Yancheng Oukai Sponge Products Co., Ltd. are chemically modified for:

Acid/Alkali Resistance: Resisting detergents with pH 5-11 without decomposing or shedding.

Weathering: For markets like the USA and Australia, we enhance UV resistance to slow down the aging of the Car Wash Sponge Brush.

Static Adsorption and Dust Management

Washing in dry seasons can create static. Yancheng Oukai Sponge Products Co., Ltd. has developed anti-static sponges to reduce charge buildup, preventing the Car Wash Sponge Brush cleaned surface from immediately attracting dust.

Frequently Asked Questions (FAQ)

Q: Why is a Car Wash Sponge Brush better than a regular cloth?

A: It offers a larger buffer space and range. The thick sponge provides deep protection, and the long handle allows you to reach the roof without touching the car body with your clothes, which could cause scratches.

Q: How to handle a leaking telescoping handle connection?

A: This is usually due to a displaced O-ring. Yancheng Oukai Sponge Products Co., Ltd. uses thickened gaskets in its designs; ensure the interface is flat or add a small amount of plumber's tape.

Q: Can Foamstar sponge brushes be used for glass?

A: Yes. Our cellulose sponges or high-density PU heads are excellent for glass, leaving no water streaks and absorbing oil films for better visibility.

Q: When should I replace my Car Wash Sponge Brush?

A: When the sponge edges tear, the material becomes sticky or hard, or water absorption drops. As an ISO 9001 factory, we recommend regular inspections for the best paint protection.

Q: Does the company support bulk custom production?

A: Yes. Yancheng Oukai Sponge Products Co., Ltd. has a 10,000-square-meter facility and advanced lines. We can customize everything from sponge density and color to handle materials for the Car Wash Sponge Brush.

English

English