For Powder Puff, we choose mainly to look at our makeup habits, the choice of powder puff when there will be texture and feel. For powder absorption and moisture control, I recommend a round powder puff. For the powder puff to make up, if it is foundation liquid and foundation cream, you can choose to use a good powder puff blister, and let it completely wet and soft up. Then squeeze out the water. Even after squeezing dry moisture, or can maintain the feeling of moisture, this time with a powder puff on the powder, the skin is better absorbed, moist, and obedient.

Strong Absorbency Expands with Water Makeup Sponge Face Washing Sponge

For the make-up people, using the makeup tools is more important, so our powder puff is the step of our makeup, for the foundation molding, the use of powder puff is also a lot of small ways. Choose a powder puff.

7*9.5*2cm It's shaped like a water drop, and the corners can be rubbed

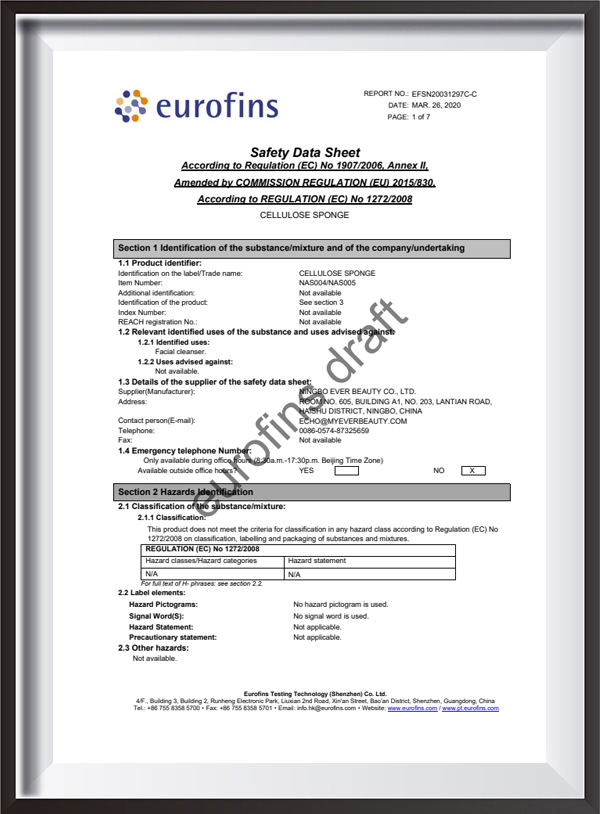

Hydrophilic non-latex, wet and dry, soak in water to enlarge, can be used to remove makeup, clean face, exfoliate and so on

Makeup, clean face

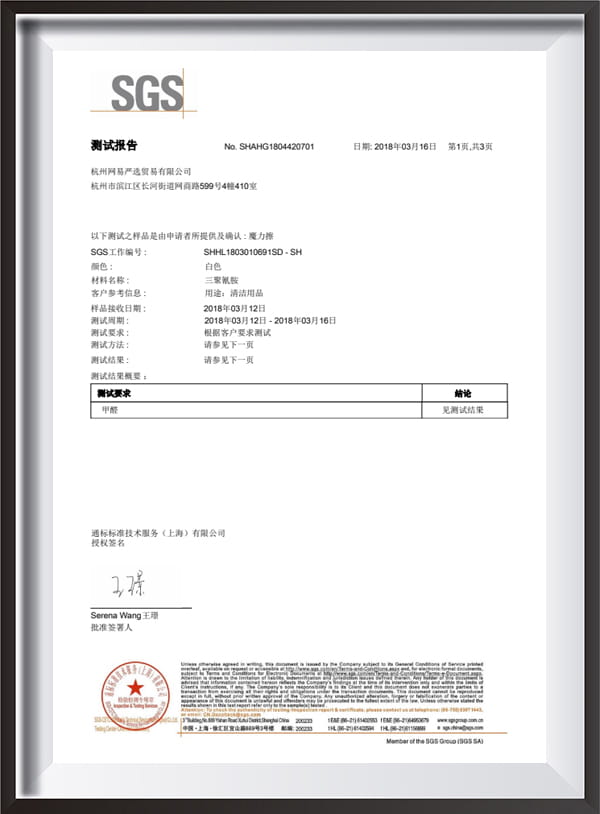

Plant fiber, skin friendly non-irritating, mild skin friendly, soft Q elastic, foaming rich

1-2 months Natural degradable material

Made of biodegradable materials that will degrade naturally after use without causing long-term pollution to the environment

Pink Green Blue Yellow Red black Grey

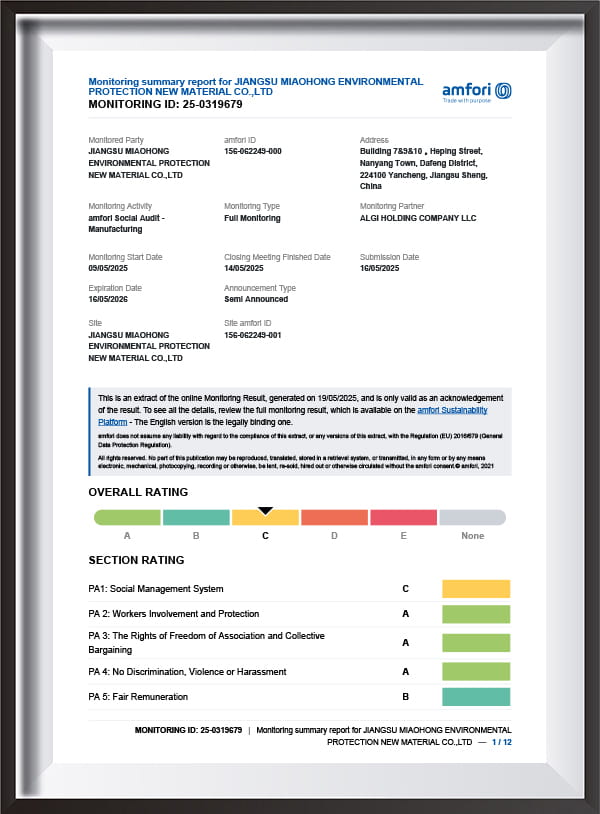

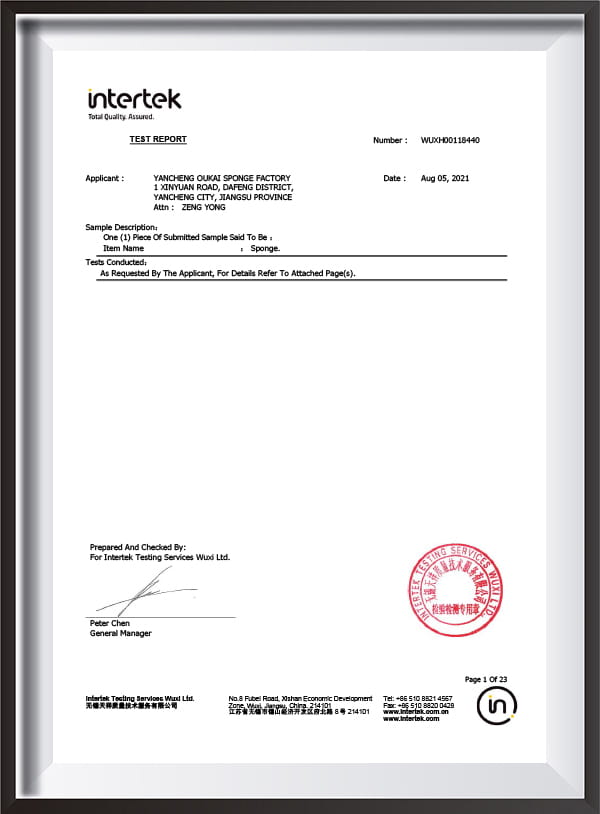

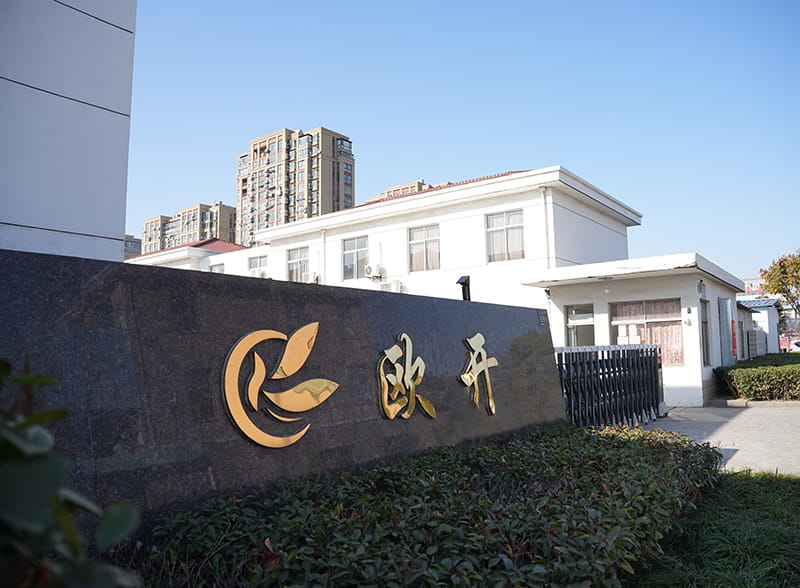

Yancheng Oukai Sponge Products Co., Ltd. was established in 2009 and covers an area of 10000 square meters.It is China Strong Absorbency Expands with Water Makeup Sponge Face Washing Sponge Suppliers and Strong Absorbency Expands with Water Makeup Sponge Face Washing Sponge Factory. Our company is located in Dafeng city. The traffic here is very convenient: only 40 kilometers from Yancheng Airport, and 30 kilometers from Dafeng Port. Our company will always follow the operation philosophy of "people-oriented, good faith, quality assurance " to provide high-quality sponge products for all clients both at home and abroad.

Our factory builds a unique processing and quality control system after a dozen years of exploration and practice. Our factory has already passed ISO 9001 quality and BSCI audits.

The company has developed more than 200 kinds of sponges, developed and produced more than 3000 kinds of sponge products, and created the Foamstar international trademark, to meet your diversified needs. The company mainly produces and sells the following products: Polyester, polyether sponge sponges (flame retardant sponge, filtration sponge, sound-absorbing sponge, anti-static sponge, seaweed cotton/coral sponge, slow rebound sponge, insulation, cleaning sponge, packing sponge), melamine sponge, wood pulp sponge (cellulose sponge), wood pulp cotton cloth, household cleaning (sponge, emery sponge, mesh cloth, microfiber cloth, cleaning brush, cleaning ball, garbage bags, plastic wrap, plastic bag), car cleaning, personal care products. Products continue to be sold to Japan, South Korea, the United States, Germany, Sweden, Britain, Canada, Australia, New Zealand, France, Italy, the Netherlands, Poland, Belgium, Spain, Russia, Chile, the United Arab Emirates, Brazil, Thailand and other more than 40 countries.

We have the advanced production equipment to meet the increasing demands of the market, as well as experienced designers and workers and a management system to help our products stand out from the others. We are a large-scale responsible factory, and the vast majority of our customers have given us a good reputation, We look forward to cooperating with you.

-

Choosing the perfect bath accessory is often an afterthought, but it is one of the most critical decisions for your daily skincare routine. A Bath Sponge Scourer is more than just a tool to soap up; i...

READ MORE -

Microfiber sponges are advanced cleaning tools made from ultra-fine synthetic fibers, often a blend of polyester and polyamide. Unlike traditional sponges, the microfibers are thousands of times finer...

READ MORE -

When it comes to choosing the right sponge for cleaning tasks, many people opt for synthetic sponges due to their availability and low cost. However, cellulose sponges are gaining popularity for their...

READ MORE -

Antibacterial kitchen clean sponges are designed to address one of the biggest hygiene challenges in the kitchen: the rapid growth of bacteria and the unpleasant odors they cause. Because sponges are ...

READ MORE

English

English