The Truth Behind the “Green” Label: Is Cellulose Truly 100% Biodegradable? As global industries and households pivot toward a circular economy, the demand for sustainable cleaning tools has reached an all-time high. The cellulose sponge is frequently marketed as the premier eco-friendly alternative ...

READ MOREProducts

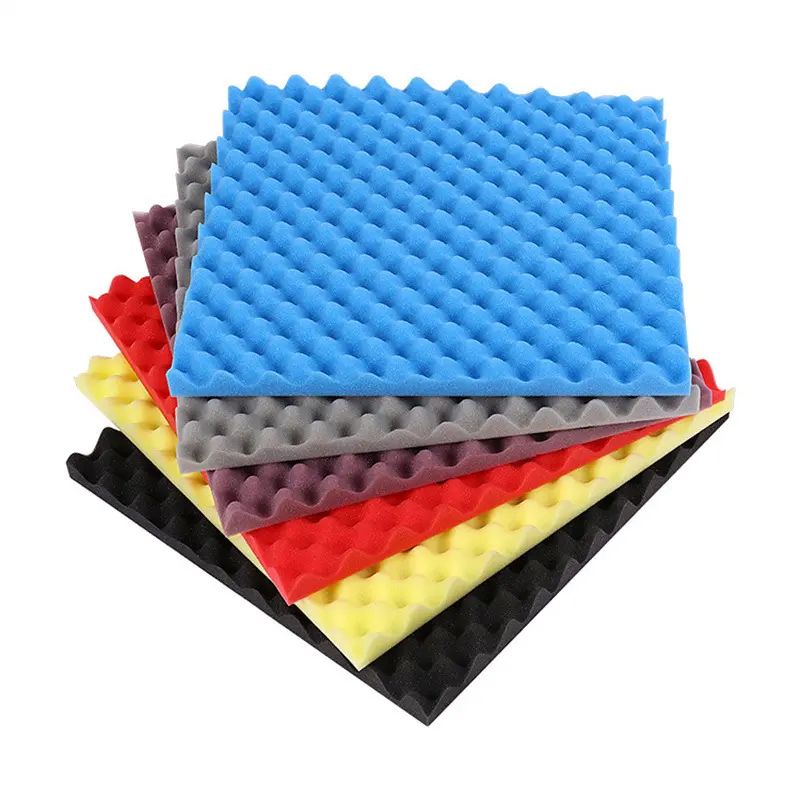

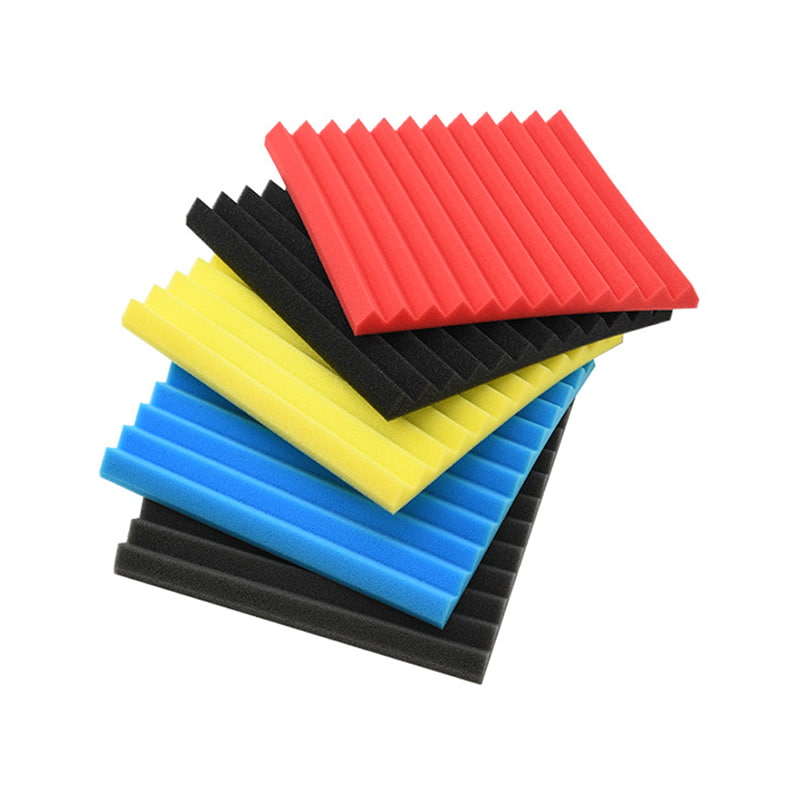

Rubber Backed Soundproofing Sponge Suppliers

Soundproofing cotton with back adhesive usually uses self-adhesive or double-sided adhesive as the back covering layer, which can be easily pasted on the surface that needs to be soundproofed. This insulation cotton is suitable for occasions that require frequent replacement or reinstallation, such as automotive interiors, speakers, etc. Soundproofing cottons with adhesive backing are easier to install and replace, while soundproofing cottons without adhesive backing are more suitable for occasions where long-term soundproofing is required.

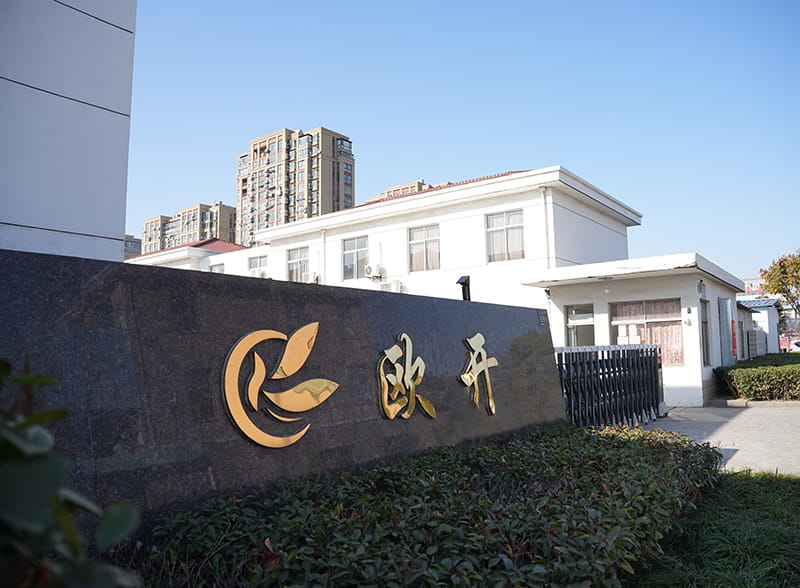

Yancheng Oukai Sponge Products Co., Ltd. was established in 2009 and covers an area of 10000 square meters.It is China Rubber Backed Soundproofing Sponge Manufacturers and Wholesale Rubber Backed Soundproofing Sponge Suppliers, Our company is located in Dafeng city. The traffic here is very convenient: only 40 kilometers from Yancheng Airport, and 30 kilometers from Dafeng Port. Our company will always follow the operation philosophy of "people-oriented, good faith, quality assurance " to provide high-quality sponge products for all clients both at home and abroad.

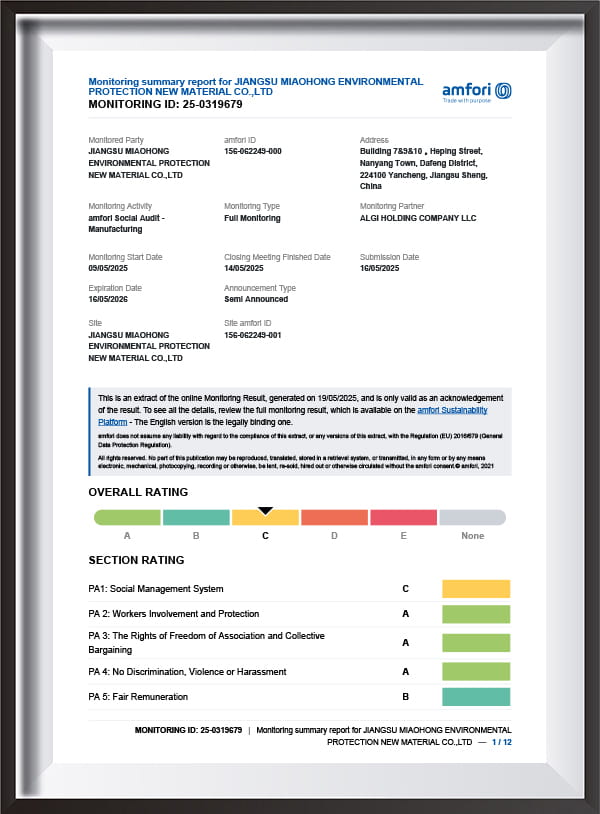

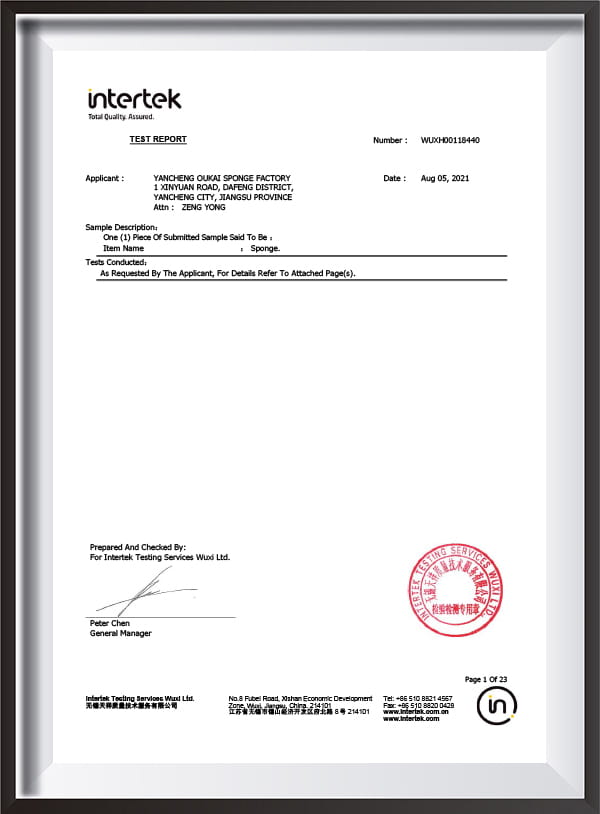

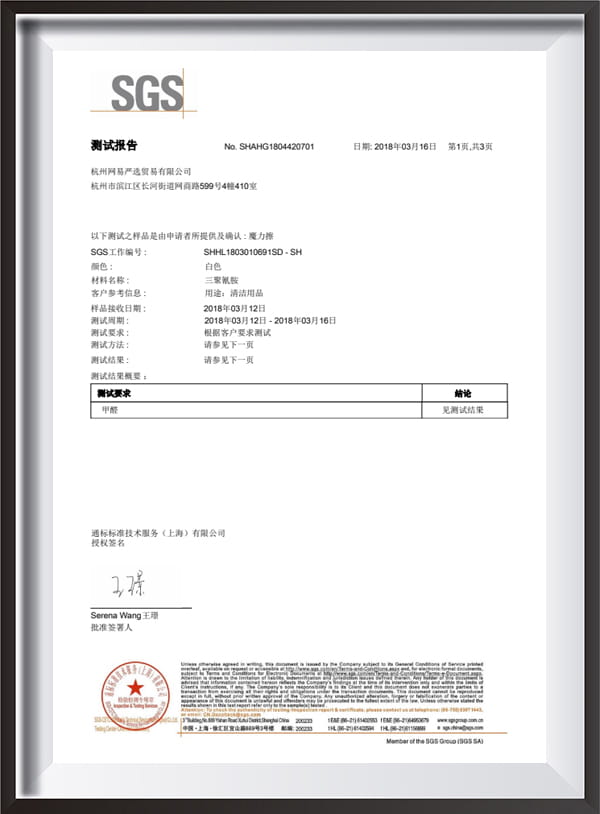

Our factory builds a unique processing and quality control system after a dozen years of exploration and practice. Our factory has already passed ISO 9001 quality and BSCI audits.

The company has developed more than 200 kinds of sponges, developed and produced more than 3000 kinds of sponge products, and created the Foamstar international trademark, to meet your diversified needs. The company mainly produces and sells the following products: Polyester, polyether sponge sponges (flame retardant sponge, filtration sponge, sound-absorbing sponge, anti-static sponge, seaweed cotton/coral sponge, slow rebound sponge, insulation, cleaning sponge, packing sponge), melamine sponge, wood pulp sponge (cellulose sponge), wood pulp cotton cloth, household cleaning (sponge, emery sponge, mesh cloth, microfiber cloth, cleaning brush, cleaning ball, garbage bags, plastic wrap, plastic bag), car cleaning, personal care products. Products continue to be sold to Japan, South Korea, the United States, Germany, Sweden, Britain, Canada, Australia, New Zealand, France, Italy, the Netherlands, Poland, Belgium, Spain, Russia, Chile, the United Arab Emirates, Brazil, Thailand and other more than 40 countries.

We have the advanced production equipment to meet the increasing demands of the market, as well as experienced designers and workers and a management system to help our products stand out from the others. We are a large-scale responsible factory, and the vast majority of our customers have given us a good reputation, We look forward to cooperating with you.

-

-

Understanding the Core Debate: Why the Tool You Choose Matters for Paint Safety When it comes to automotive maintenance, the car wash sponge vs. microfiber wash mitt debate is one of the most persistent topics in the detailing community. For a car owner or a professional detailer, the ultimate goal ...

READ MORE -

In the professional cleaning industry and high-end household maintenance, the choice of tools directly impacts the quality of the finish. For years, the market was dominated by cellulose and foam products, but the emergence of the microfiber sponge has fundamentally changed the standard for “clean.”...

READ MORE

Technical Advantages of Rubber Backed Soundproofing Sponge

The technical performance of Rubber Backed Soundproofing Sponge in controlling noise arises from a combination of acoustic design principles and engineered structure. For applications where sound must be minimized in industrial, automotive, architectural, or consumer environments, this type of material offers a sophisticated approach to noise mitigation that goes beyond bulk absorption. At the heart of this capability is the intelligent pairing of an open‑cell sponge foam layer with an elastomeric rubber backing that works in concert to manage both airborne and structure‑borne sound. Yancheng Oukai Sponge Products Co., Ltd. has invested considerable expertise into optimizing this dual‑layer system so that each layer complements the other’s performance without compromise.

Airborne sound absorption begins with the open‑cell structure of the sponge, which is engineered with a network of interconnected pores. When sound waves enter this porous network, the motion of air within the pores causes friction against the internal cell walls. This friction transforms kinetic sound energy into thermal energy, effectively reducing the intensity of the sound as it moves through the material. Importantly, the pore size, distribution, and cell wall thickness are controlled meticulously during production, ensuring wide‑band absorption rather than absorption limited to narrow frequency bands. For Yancheng Oukai Sponge Products Co., Ltd. this means that the resulting product exhibits predictable and measurable performance in real operational environments, whether installed inside machinery enclosures, within vehicle cabins, or mounted on building panels.

In addition to absorption, sound blocking is achieved through the dense rubber layer bonded to the back of the sponge. This layer increases the composite’s acoustic mass, which according to mass‑law acoustics directly impedes the transmission of sound waves through the barrier. In practical terms, when sound waves reach the interface of the sponge and rubber, the rubber layer’s density reflects and resists further transmission. This is particularly important at lower frequencies where lightweight materials alone would be ineffective. By combining these two mechanisms — energy dissipation in the foam and resistance in the rubber — Yancheng Oukai Sponge Products Co., Ltd. delivers a solution that both intercepts noise before it proliferates and prevents residual noise from passing through barriers into quiet zones.

Structure‑borne vibration presents another challenge for noise control, especially in industrial settings where heavy machinery generates persistent vibration. The elastomeric quality of the rubber backing layer contributes significant vibration damping because of its viscoelastic behavior. Under dynamic mechanical stress, the rubber absorbs vibrational energy through internal deformation processes, converting it into insignificant heat that does not contribute to audible noise. This function is particularly beneficial when Rubber Backed Soundproofing Sponge is applied to surfaces prone to resonance, such as metal frames or ductwork. By reducing the mechanical energy before it radiates as sound, Yancheng Oukai Sponge Products Co., Ltd. ensures the material performs as a comprehensive noise control medium across a broader range of real‑world conditions than simple foam products could ever achieve alone.

Understanding the technical advantages of Rubber Backed Soundproofing Sponge requires a thorough examination of its engineered material properties. This acoustic solution does not function effectively by accident; rather, it arises from deliberate design choices in polymer chemistry, cellular morphology, and composite bonding. Yancheng Oukai Sponge Products Co., Ltd. has developed proprietary blends of polymer precursors and foaming agents that produce open‑cell structures with consistent performance attributes, while also integrating carefully formulated elastomeric backings to complement the foam’s acoustic behavior. The result is a material whose physical properties have been optimized for performance, durability, and adaptability.

The open‑cell sponge component must balance two critical but often competing design requirements: porosity for sound absorption and physical stability for installation and long‑term service. High porosity increases the available internal surface area for sound wave interaction, enhancing the material’s ability to dissipate acoustic energy. However, without adequate mechanical stability, a highly porous foam can collapse under compression or degrade under cyclic loads. To address this, Yancheng Oukai Sponge Products Co., Ltd. employs precision formulation and controlled foaming conditions that yield a uniform distribution of pores with well‑defined geometry. This controlled architecture supports strong acoustic interaction while maintaining resilience against compression and deformation during handling, shaping, and installation.

Foam density is another critical parameter that influences acoustic behavior and physical performance. A foam that is too low in density may provide excellent absorption but will lack the mechanical integrity needed for real‑world applications. Conversely, a foam that is overly dense can compromise acoustic performance by reducing pore interconnectivity. Through iterative formulation adjustments and quality control techniques, Yancheng Oukai Sponge Products Co., Ltd. has achieved a density range that optimizes performance for a broad spectrum of use cases — from high‑performance industrial noise mitigation to consumer product acoustics and architectural sound control.

The rubber backing layer, often composed of a blend of synthetic elastomers and reinforcing fillers, serves to increase acoustic mass while maintaining flexibility. In acoustic composites, a balance between mass and flexibility is necessary because excessive stiffness can hinder vibration damping, and insufficient mass can reduce sound blocking capacity. Through its research and development efforts, Yancheng Oukai Sponge Products Co., Ltd. has formulated rubber compounds that provide significant mass loading without compromising elasticity. This balance ensures that the composite material resists sound transmission while retaining the ability to absorb mechanical energy through internal molecular friction.

Bonding between the foam and rubber layers is another aspect of material engineering that directly impacts performance. A weak interface would result in delamination under thermal cycling, humidity changes, or mechanical vibration. For this reason, Yancheng Oukai Sponge Products Co., Ltd. uses advanced adhesion promoters and lamination techniques to create a durable interface that maintains structural integrity under varied operating conditions. This durable bond ensures that the acoustic benefits provided by each layer are sustained over the long term, even in challenging environments.

By focusing on engineered material properties — from pore structure to rubber compound selection and composite bonding — Yancheng Oukai Sponge Products Co., Ltd. ensures that Rubber Backed Soundproofing Sponge provides consistent, measurable, and reliable performance that meets the needs of demanding acoustic applications.

Rubber Backed Soundproofing Sponge must perform reliably not only acoustically, but also under a wide range of thermal and environmental conditions encountered across industrial, commercial, and residential applications. Environmental robustness is an essential technical advantage because acoustic materials are frequently exposed to temperature extremes, moisture, chemical atmospheres, and UV radiation. Yancheng Oukai Sponge Products Co., Ltd. designs and tests its soundproofing composites with these real‑world stresses in mind to ensure consistent performance and durability.

Thermal stability is one critical aspect of environmental performance. In applications such as automotive engine bays, HVAC systems, or industrial enclosures, temperatures can fluctuate dramatically. The open‑cell foam and elastomeric backing must retain their acoustic and mechanical properties without softening, embrittling, or undergoing dimensional change. Yancheng Oukai Sponge Products Co., Ltd. achieves this by selecting polymers and curing processes that provide a wide operating temperature range, allowing the material to remain flexible in cold environments and resist deformation at elevated temperatures. This thermal resilience ensures that acoustic performance does not degrade as conditions change, preserving noise control effectiveness over the life of the installation.

Moisture resistance is another key attribute, especially in environments with high humidity, condensation, or direct exposure to water. Standard open‑cell foams could absorb moisture, which would reduce acoustic performance and promote mold growth. To mitigate these risks, Yancheng Oukai Sponge Products Co., Ltd. integrates hydrophobic additives into the foam formulation and relies on the rubber backing as a moisture barrier. This combination prevents significant moisture ingress and preserves acoustic function. In HVAC ducts, marine settings, or outdoor installations, this ability to resist moisture translates into long‑term operational stability without the need for frequent maintenance or replacement.

Chemical resistance is crucial in industrial environments where solvents, oils, or corrosive gases may be present. Exposure to harsh chemicals can degrade polymer structures and result in loss of both mechanical and acoustic performance. Yancheng Oukai Sponge Products Co., Ltd. conducts formulation screening and accelerated aging tests to ensure that Rubber Backed Soundproofing Sponge withstands exposure to common industrial contaminants. This resistance improves the material’s service life in automotive plants, manufacturing facilities, and chemical processing environments where robust acoustic performance is needed alongside environmental tolerance.

Ultraviolet (UV) exposure, while often overlooked, can also affect acoustic materials that are installed outdoors or near windows and skylights. UV radiation can cause polymer chains to break down over time, leading to surface embrittlement and discoloration. Yancheng Oukai Sponge Products Co., Ltd. incorporates UV stabilizers into both foam and rubber components to protect against this degradation. As a result, the material maintains its structural and acoustic integrity even after prolonged exposure to sunlight.

By engineering Rubber Backed Soundproofing Sponge for thermal stability, moisture resistance, chemical resistance, and UV protection, Yancheng Oukai Sponge Products Co., Ltd. ensures this acoustic solution is reliable and durable across diverse environmental conditions. This robustness enhances performance longevity, reduces lifecycle costs, and expands the range of applications where high‑performance acoustic control is realistic and sustainable.

The mechanical performance of Rubber Backed Soundproofing Sponge is a defining technical advantage that enables the material to withstand installation demands, operational stresses, and long‑term service conditions. In many acoustic applications, materials are subject to mechanical loads, compressive forces, vibration cycles, and handling stresses that can compromise performance if the material is not engineered with appropriate mechanical resilience. Yancheng Oukai Sponge Products Co., Ltd. has tailored the composition and structure of its acoustic composites to ensure mechanical performance that enhances durability, resilience, and service life.

One dimension of mechanical performance is compressive behavior. Acoustic materials often must be fitted into panels, gaps, or joints where compression occurs. A poor‑quality material would deform, lose thickness, and fail acoustically over time. The open‑cell foam used by Yancheng Oukai Sponge Products Co., Ltd. is engineered for excellent rebound performance — it returns to its original geometry after repeated compressive loads without permanent deformation. This resilience helps preserve acoustic performance even when the material is installed in confined spaces or subjected to repeated mechanical stresses.

Tensile and tear strength are also crucial. Applications such as automotive interiors, vibration isolation mounts, or industrial enclosures require materials that can resist tearing during handling, shaping, and assembly. The rubber backing contributes significantly to tensile strength by absorbing and redistributing mechanical loads that might otherwise cause foam rupture. Yancheng Oukai Sponge Products Co., Ltd. designs the elastomeric layer with reinforcing fillers and optimized cure systems to enhance both tensile integrity and flexibility. This reinforcement ensures that Rubber Backed Soundproofing Sponge resists tearing under shear or pull forces encountered during installation or operation.

Fatigue resistance under cyclic loading is another mechanical characteristic that enhances durability. In environments where machinery vibration, thermal cycling, or repeated movement occurs, material fatigue can lead to micro‑cracks, delamination, or stiffness loss. Yancheng Oukai Sponge Products Co., Ltd. selects polymer systems and bonding techniques that provide excellent fatigue resistance, enabling the composite to maintain structural coherence and acoustic function over thousands of load cycles without significant degradation.

Mechanical performance extends to resistance against impact and abrasion. Acoustic materials used in industrial or high‑traffic environments may encounter incidental contact with tools, parts, or mobile equipment. The rubber backing layer provides a protective surface that absorbs impact energy and resists surface abrasion, preventing premature wear. By combining robust foam resilience with protective backing performance, Yancheng Oukai Sponge Products Co., Ltd. ensures that the acoustic material sustains both its mechanical integrity and sound control capabilities in demanding contexts.

In real‑world applications, mechanical performance intersects directly with long‑term durability and service life. By engineering Rubber Backed Soundproofing Sponge for superior compressive response, tensile and tear resistance, fatigue tolerance, and impact resilience, Yancheng Oukai Sponge Products Co., Ltd. delivers an acoustic solution capable of sustaining consistent performance through handling, installation, and years of operational stress. This mechanical robustness reduces the likelihood of premature failure and enhances reliability across diverse noise control applications.

English

English